If we go back into the history of machines, we see all devices were mechanical, and manual i.e. requires a proper man’s effort and time for the operation. With time, advance things came into being to reduce man’s energy, and time consumption. But, how things transformed into the automatic scenario? Let’s take an example of a car, in the beginning, cars were without air conditioners, and without power staring, but then some new devices were installed in a vehicle to make it soft and comfortable. Similarly, some tools are very much responsible for performing some specific operation with the help of machines. Pancake type Slip rings are one of those fantastic devices.

What are Pancake Type Slip Rings?

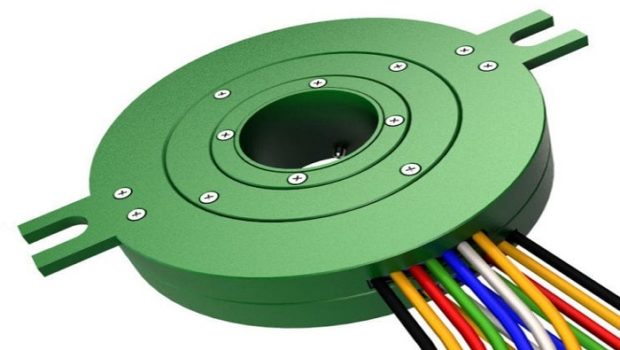

Let’s understand the definition of pancake type slip rings, word by word. As the name suggests, slip rings identify that the device will have a ring that will slip or rotate. So, pancake type slip rings are those slip rings which have a structure just like a pancake, flat with negligible height.

Usually, slip rings are used to transfer electric signals from one part of the machinery to others. Now a question arises that if transmission of some electric current is required, then why we’re not using a set of wires for this purpose? Cables are used to transfer the electricity between static parts, and we can’t use wires if our subject is moving continuously. That’s why we use slip rings or pancake type slip rings.

So, a device which handles the transportation of electric voltages within a machine between two components of the machine, providing a condition that one part is stationary and the other part is static or stable, and the height is negligible, is called pancake type slip ring.

Working Of Pancake Type Slip Rings

As we discussed earlier, slip rings are used to establish an electrical connection between a static and rotating component of a device. Similarly, general pancake type slip rings have two parts one is stationary, and the other one is rotatory made up of different materials based on the requirements.

When electric voltage passes from this device, the static part takes signals as an input and provides output to ring. The rotation of rings makes a connection and transmission occur which further operate the machine to perform any specific function.

Uses of Pancake Type Slip Rings

Pancake type Slip Rings are utilized in different electromechanical gadgets where a height space is very less. Why? Because of the base structure of these slip rings. A portion of its applications are:

Engines & Motors – This kind of slip ring is utilized in engines that are being used in another sort of machines. These overwhelming engines are being used in the cement enterprises.

Seaward Cranes – Mostly, these cranes have a mix of various kinds of slip rings in them. Be that as it may, the Pancake Slip Ring is likewise utilized in these kinds of cranes.

Microwave – One of its noteworthy uses is in microwaves. The rotatory plate in stoves has a pancake slip ring which turns it.

Car Showrooms – This kind of slip ring is utilized in the auto showrooms, where solid mass is displayed in a rotatory movement. Ordinarily, vehicles are moved in a roundabout way to indicate it to the clients. The pancake-type slip ring is behind that pivot.

Things you should keep in mind while hitting the market for Pancake type Slip rings.

Now that we know every crucial detail about the pancake slip rings, we still want to clear some points that will help in buying the best slip ring from the market. Let’s have a look at the essential factors for purchasing a perfect slip ring according to your need.

Temperature Conditions – The first thing is to go through the temperature changes where you’re about to install a slip ring. If you’re planning to operate it in a hot environment, you must tell your supplier about your surrounding temperature so that you may not get in trouble during your work.

High Altitude – If your plant is a considerable height from the sea level, you must tell your vendor about it. Most of the slip rings are designed to perform at sea level only, so better communicate with the supplier about the height of your plant.

Rotating Speed – Rotating speed refers to rotation per minute, i.e. RPM. If your machine requires a high rotation speed, then highlight this property in your requirement table. In this way, you will get the best thing according to your need. As a result, your slip ring will last long with high efficiency.

Best Models of Pancake Slip Rings

We’ve gathered a rundown of organizations which produce fantastic slip rings. Their best models with their notable highlights are given beneath:

SNK Series – Senring is manufacturing slip rings which are best for constrained tallness frameworks. SNK arrangement hotcake slip rings give low-rubbing and low-obstruction.

JINPAT Company – Their LPK series slip rings have a base thickness of 6mm, low clamors, and high pivot speed. Best of all, you don’t need to stress over the association drop. Their innovation kills association drop situation.

MP220 Series – Moflon’s pancake-type slip rings have a thickness ranges from 18mm to 22mm, and the structure is comprised of aluminum combination. The claim to fame of their slip rings is that the variety of obstruction will be low.

Rotarix Pancake Slip Rings – The pivoting rate of these slip rings up to 300rpm. Lodging is comprised of aluminum amalgam, and temperature ranges from – 30°C to +80°C.

These were some points that are very much essential for your hunt for a slip ring. But, still, nobody tell you better about your needs than you. So, you must study the behavior of your plant in which you’re planning to install a slip ring. If you want further details about the models mentioned above and companies, you can visit their official website and download the catalogue of any model.

If you think we’ve missed anything related to high temperature slip ring, you can inbox us. We’ll give you a further detailed description about slip rings or rotatory unions etc.

Related Posts